Phosphorsäure Engpass: Aktueller Rohstoffmarkt und alternative Lösungen für die Zukunft

Die Störung der Weltwirtschaftsströme hat nun auch die die Phosphatindustrie erreicht. Phosphorsäure wird immer knapper und immer teurer. Betrachtet man die enorme wirtschaftliche Relevanz von Phosphorsäure, stellt sich die aktuelle Situation durchaus als besorgniserregend dar. Mit einer kurzfristigen Entspannung der unsicheren Versorgungslage ist aufgrund der Eskalation politischer Gegebenheiten nicht zu rechnen.

Wie es um die Verfügbarkeit von Phosphorsäure aus heutiger Sicht bestellt ist und wo alternative Lösungen möglich sind, beleuchten wir in diesem Beitrag.

Phosphorsäure: Ein Rohstoff mit vielen Anwendungen

Die Bedeutung von Phosphorsäure als eine der wichtigsten anorganischen Chemikalien in Europa ist nicht zu unterschätzen. Sie dient als Ausgangsstoff zur Herstellung phosphathaltiger Düngemittel und wird in zahlreichen Industriesektoren eingesetzt, darunter Bauindustrie, Elektronik, Lebensmittel und Getränke, Tierfutter, Reinigungsmittel, Wasseraufbereitung, Pharma und Körperpflege.

Ein kurzer Überblick der verschiedenen Einsatzbereiche:

- Düngemittelherstellung bzw. Einsatz in der Landwirtschaft

- Lebensmittelindustrie (Antioxidans, Säureregulator, Aromastoff), Reinigungsmittel in der Lebensmitteltechnologie, Tonizitätsmittel bei der Herstellung von Erfrischungs- und Sodagetränken, Raffination von Zuckern, Fetten und Ölen, Herstellung von Erfrischungs- und Sodagetränken

- Nährstoff in der Fermentation

- Abwasserbehandlung

- Zahnbehandlungen (Zahnzement, Ätzlösungen, Zahnaufhellung, Zahnbelagentfernung)

- Reinigungsmittel im Baugewerbe

- Legierungszusatz bei Eisen und Zink als Schutz gegen Korrosion

- Rostentferner, Rostumwandler

- Nass-Ätzmittel (Halbleiter)

- Flussmittel zum Löten

- Ätzen von Siliziumnitrid (Mikroelektronik)

- Elektrolyt in Phosphorsäure-Brennstoffzellen

- Elektrolyt beim Elektropolieren von Kupfer zum Entgraten

- Herstellung von Pufferlösungen

- pH-Wert Regulierung bei Hydrokulturen

- Herstellung von Spezialkatalysatoren, Aktivkohle, Gelatine, Hydroxylamin und anderen reinen anorganischen und organischen Phosphorverbindungen

Phosphorsäure wird zum Ätzen von Wafern verwendet.

Europa ist bei Rohphosphat zu 100 Prozent importabhängig

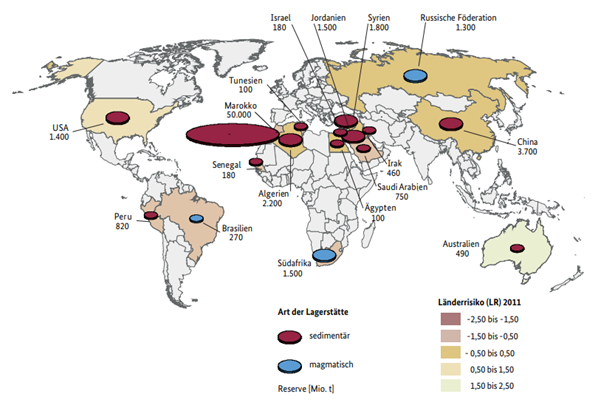

Österreich ist wie die meisten Länder der Europäischen Union bei Phosphat-Produkten nahezu vollständig von Importen abhängig. Phosphate werden in Asien, Nordafrika, Nordamerika und Nahost in Erzlagerstätten unterschiedlicher Qualität und Größe abgebaut.

Rund 80 Prozent des weltweit abgebauten Rohphosphats wird direkt vor Ort zu Phosphorsäure oder fertigen Düngemitteln weiterverarbeitet.

Die größten Produzentenländer sind China, Marokko und die USA, die zusammen zwei Drittel aller Phosphate fördern. Weisser Phosphor, der in Europa zur Erzeugung thermischer Phosphorsäure benötigt wird, kommt aus Kasachstan, Vietnam und China.

China besitzt zwar nur 5 Prozent der Gesamtreserven (3,2 Milliarden Tonnen), ist aber mit 90 Millionen Tonnen (2020) der größte Phosphat-Produzent. Im Vergleich zu Vorjahren fördert das Land jedoch deutlich weniger (2017: 120 Mio. t), da die Bergbau- und Verarbeitungsindustrie Chinas mit Umweltgebühren, höheren Produktionskosten und Stillständen aufgrund von Wasserverschmutzung und anderen Umweltproblemen zu kämpfen hat.

Die meisten Phosphatreserven der Welt befinden sich in Marokko, die etwa 70 Prozent der Gesamtreserven (50 Milliarden Tonnen) ausmachen. Das Land ist mit 37 Millionen Tonnen (2020) der zweitgrößte Produzent, wobei der Großteil der Produktion aus der Bou Craa-Mine in der Westsahara stammt.

Die USA sind mit 24 Millionen Tonnen (2020) drittgrößter Phosphat-Produzent, obwohl die US-Reserven nur 2 Prozent der weltweiten Reserven ausmachen.

Phosphatreserven weltweit: Die Weltkarte zeigt 99 Prozent der weltweit bekannten Phosphatlagerstätten mit weniger als 100 Millionen Tonnen Phosphatvorkommen. Quelle:

BGR

Phosphatgestein als Basis der Industrie

Die Rohstoffbasis für Phosphorsäure bildet Phosphatgestein (Rohphosphat). Das Rohphosphat wird nach dem Abbau aufbereitet und anschließend im Nassverfahren oder thermischen Verfahren zu Phosphorsäure weiterverarbeitet.

1. Nassverfahren benötigt Schwefelsäure

Im Nassverfahren wird Phosphorsäure durch die Reaktion von konzentriertem Rohphosphat mit Schwefelsäure erzeugt. Das Nassverfahren produziert unreine Phosphorsäure mit einer Konzentration von etwa 56 Prozent, die als Ausgangsmaterial für Düngemittel, flüssige Düngemittel und Rohphosphorsäure (Merchant-Grade Phosphoric Acid – MGA) verwendet wird. Rohphosphorsäure kann zudem eingedampft werden, um reine Phosphorsäure sowie Phosphorsäure mit Lebensmittelqualität oder pharmazeutischer Qualität zu erhalten.

2. Thermisches Verfahren basiert auf weißem Phosphor

Der thermische Prozess der Phosphorsäure-Produktion umfasst die Verbrennung elementaren Phosphors zu Phosphorpentoxid und anschließende Hydrolyse. Für das Verfahren wird meist elementarer weißer Phosphor verwendet. Thermische Phosphorsäure weist eine sehr hohe Reinheit auf und ist für den Lebensmittel- und Pharmasektor von hoher Relevanz.

Rohphosphat, meist Apatit, stammt großteils aus Lagerstätten außerhalb Europas.

Rohstoffverknappung katalysiert die Phosphorsäure Preise

Der Preis für Phosphorsäure hat sich seit Beginn 2021 um das 3- bis 4-fache erhöht und liegt aktuell bei mehr als 3.000 Euro/Tonne. Die Ursachen der Verknappung bzw. Preissteigerung sind vielfältiger Natur und aufgrund ihrer Komplexität derzeit kaum überschaubar. Die hier getroffenen Aussagen sind daher auch mit gewissen Unsicherheiten behaftet. Grundsätzliche Einflussfaktoren sind jedoch neben Verfügbarkeit und Preis von Rohphosphat bzw. weißem Phosphor die Bezugspreise anderer Schlüsselkomponenten wie Schwefelpreis, Energiekosten und Transportkosten.

Versorgungsschwierigkeiten mit weißem Phosphor

Mehrere große Phosphorsäure-Produzenten in Europa haben derzeit erhebliche Schwierigkeiten mit der Beschaffung von weißem Phosphor aus Zentralasien. Die Hersteller können nicht mehr die vollen Mengen zur Verfügung stellen. Eine Kompensation des Ausfalls durch andere Hersteller scheint derzeit nicht möglich.

Weißer Phosphor

Weißer Phosphor,

BXXXD,

CC BY-SA 3.0

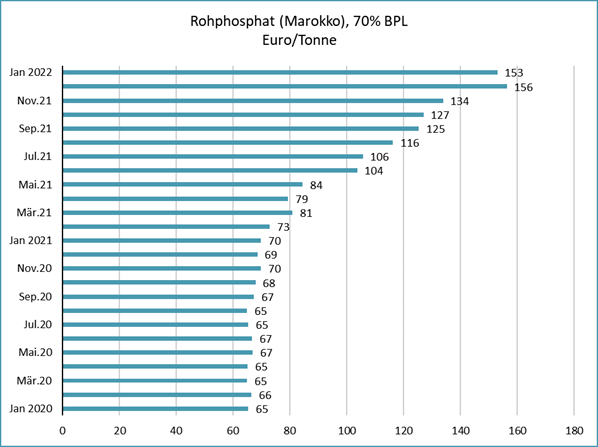

Hohe Preise für Rohphosphat

Die Preise für Rohphosphat steigen seit Herbst 2020 kontinuierlich an und liegen aktuell bei 153 Euro/Tonne (31.1.2022). Das entspricht einer Erhöhung um 134 Prozent im Vergleich zum Frühjahr 2020 (65 Euro/Tonne).

Quelle:

index mundi

Schwefelsäure verfügbar, aber teuer

Für die Herstellung von Phosphorsäure im Nassverfahren benötigt man große Mengen an Schwefelsäure. Mit über 60 Prozent des gesamten Weltverbrauchs ist die Produktion von Düngemitteln der wichtigste Endverbrauchermarkt für Schwefelsäure.

Der Engpass bei Schwefelsäure hat sich seit letztem Jahr zwar etwas entspannt, die Preise sind allerdings aufgrund des niedrigen Fördervolumens der Raffinerien auf einem hohen Niveau. Schwefelsäure muss nun wieder aus elementarem Schwefel in flüssigen Schwefel umgewandelt werden, um daraus Schwefelsäure zu gewinnen.

Das treibt die Schwefelsäure-Preise in die Höhe und beeinflusst indirekt auch die Herstellungskosten der Phosphorsäure aus dem Nassverfahren.

Ab dem 2. Quartal 2022 ist mit einer Verschärfung der Situation zu rechnen, da in einigen Raffinerien Wartungsarbeiten durchgeführt werden. Die Anlagen sind für drei bis sechs Wochen stillgelegt, wodurch die Verfügbarkeit von Schwefel in Europa wieder zunehmend unter Druck geraten wird.

Näheres zur Verknappung der Schwefelsäure und den damit verbundenen Auswirkungen erfahren Sie unseren Blogbeiträgen

Schwefelsäure: Warum der saure Alleskönner von extremer Verknappung betroffen ist und

Schwefelsäure Engpass: Gravierende Auswirkungen auf die Industrie.

Die Verfügbarkeit von Phosphorsäure bleibt knapp

Die eklatante Unterversorgung mit Phosphorsäure in Europa wird unserer Einschätzung nach zumindest bis zum Sommer anhalten. Selbst wenn die Rohstoffversorgung in den nächsten Monaten wieder ins Laufen kommen sollte, wird der hohe Nachholbedarf die Landwirtschaft und verschiedene andere Industriezweige nachhaltig stören.

Die Donauchem muss Phosphorsäure derzeit kontingentieren, verfügt aber nach wie vor über Reserven. Aufgrund unserer guten Kontakte zu Lieferanten und unserer 2-Lieferantenstrategie sind wir trotz der schwierigen Versorgungssituation noch in der Lage, für unsere Kunden Ware zu beschaffen.

Sollte sich die Versorgungslage weiter zuspitzen, erarbeiten wir individuell für Kunden passende Alternativen aus unserem breiten Sortiment an anorganischen Säuren oder finden eine adäquate Lösung. Eine gewisse Flexibilität in Bezug auf mögliche Alternativen ist seitens der Donauchem gegeben.

Prüfen Sie alternative Säuren für Ihre Anwendung

Eine breite Palette von Lösungen steht bei Anwendungen offen, die Phosphorsäure zur Regulierung des pH-Wertes nutzen (z.B. Abwasserneutralisation, Reinigungsmittel-Bereich).

Eines der möglichen Ersatzprodukte ist zum Beispiel Amidosulfonsäure, die seit kurzem von der Donau Chemie Gruppe in Pischelsdorf produziert wird. Bei Anwendungen, die Phosphorsäure als Nährstoff nutzen, ist der Ersatz durch eine andere Säure nicht möglich. Es kann jedoch eine Reduktion des Mengenverbrauchs angestrebt werden, etwa in der Landwirtschaft.

Fazit: Regionale Alternativen für Phosphorsäure

Mit einer zeitnahen Entspannung der Rohstoffsituation ist aus heutiger Sicht nicht zu rechnen. Angesichts der labilen Lage auf den globalen Rohstoffmärkten lohnt es sich, über regionale Phosphorsäure-Alternativen nachzudenken. In vielen Anwendungsbereichen ist der Ersatz von Phosphorsäure durch andere anorganische Säuren möglich. Kontaktieren Sie uns gerne, um die Optionen für Ihre Anwendung auszuloten und eine passende Lösung auszuarbeiten.

Aufgrund der aktuellen politischen Lage ist eine Entspannung der momentanen Phosphorsäure-Situation nicht in Sicht!

www.donauchem.at

www.donauchem.at