Although plastics have not been around for very long, it is hard to imagine our everyday life without them. Plastic products can be found in almost all areas of life. Without them, hygienically packaged food, medical supplies and numerous technical components for the electrical, construction and automotive industries would not be possible.

How plastic conquered the world

The first plastics were developed at the turn of the century on the basis of natural materials. They imitated ivory and silk and initially occupied only a market niche. It was also at this time that the first companies were established in Austria that produced buttons, combs and fashion items from these plastics. In 1911, cellulose production in the form of sheets, rods and tubes followed with the founding of the "Österreichische AG für Zelluloid Fabrikation".

The first fully synthetic plastic was invented by Leo Hendrik Baekeland in 1907. He called his invention "Bakelite" in reference to his name. The synthetic resin mass could be pressed into moulds and hardened by heat and pressure. After the patent expired in 1927, Bakelite production also spread to Austria. By the mid-1930s, there were already more than thirty synthetic resin pressing plants with around 2,000 employees. Shortly afterwards, the first injection moulding machines also came into use.

The market introduction of PVC at the end of the 1930s marked another milestone in the history of plastics. However, the plastic boom did not begin until after the Second World War in the 1950s and 1960s. Along with polyethylene and polypropylene, PVC advanced to become the most important plastic for the manufacture of a variety of household and industrial products. The market recorded double-digit growth rates. In 1950, the per capita consumption of processed plastics in Austria was only 0.3 kg. In 1970 it was already 37.6 kg, in 1980 it rose to 98.8 kg and today it is about 150 kg (including resins for varnishes, glues etc.).

What are plastics actually?

Plastics are man-made macromolecules (polymers) composed of a large number of repeating organic molecules (monomers). If polymers consist of only one monomer, they are called homopolymers. If the polymers are made of at least two different types of monomers, they are called copolymers. Due to their lower melting point, copolymers are more durable and more resistant to bending than polymers.

Most plastics consist of the elements carbon (C), hydrogen (H) and oxygen (O). Less frequently, nitrogen (N), sulphur (S), chlorine (Cl), fluorine (F) or silicon (Si) are also found.

Polymers + additives = plastic

Compared to other materials, plastics have a wide range of physical properties that make them attractive as materials:

- Lightness: their density is only about half that of glass, porcelain or light metal. This makes them an efficient packaging material and, as a material in vehicles, reduces fuel and energy consumption.

- Insulation capacity: Almost all plastics are non-conductors and insulate well against electricity and heat. A 5 cm thick insulating layer of plastic foam, for example, reduces the heating costs of a single-family house by almost half.

- Mouldability: They can be moulded easily and cheaply.

- Flexibility: They can be "tailor-made" depending on the intended use.

- Resistance: They are resistant to water, many also to acids and alkalis, and they do not oxidise.

Most plastics contain so-called additives in addition to the polymers to improve certain material properties or to facilitate processing. Accordingly, a distinction is made between functional additives (e.g. plasticisers, antistatics, colourants) and processing aids (e.g. lubricants, stabilisers, blowing agents).

The wide range of possibilities for compounding and processing polymers and additives results in an immense spectrum of materials, including high-performance plastics. In total, more than 200 types of plastics are known today.

Synthetic plastics versus bioplastics

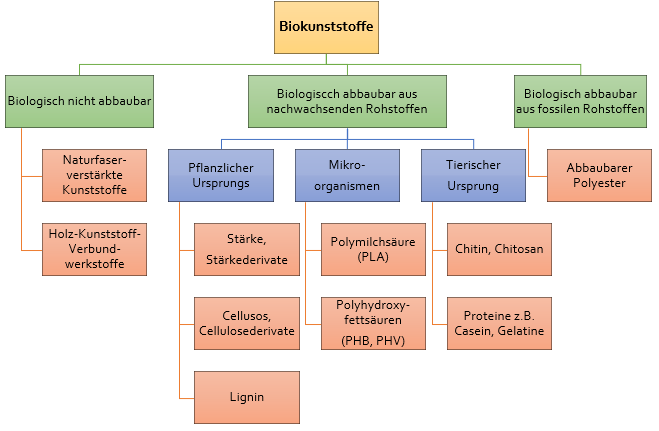

The vast majority of plastics are produced from petroleum through chemical synthesis. In addition to synthetic plastics, semi-synthetic, biodegradable plastics based on plant and animal sources as well as other forms of bioplastics are becoming increasingly important.

1. synthetic plastics based on crude oil

In the production of synthetic plastics, petroleum is first separated by distillation into liquid and gaseous components as well as various residues. This produces crude petrol (naphtha), which is split into ethylene, propylene, butylene and other hydrocarbon compounds by the so-called cracking process.

This is followed by synthesis, in which heat, solutions or pressure are used to produce net- or chain-shaped polymers from the monomers (polyaddition, polymerisation, polycondensation, copolymerisation). The name of the plastic reflects which components were used for its production, e.g. polyethylene or polypropylene.

2. semi-synthetic and other bioplastics

Semi-synthetic bioplastics (biopolymers) are produced by chemical modification of a natural polymer (rubber to rubber, cellulose to celluloid) or by polymerisation of biological molecules (lactic acid to polylactic acid, starch to thermoplastic starch). The most important bioplastics include:

- Polyethylene furanoate (PEF)

- Thermoplastic starch (TPS)

- Cellulose acetate (CA)

- Polylactide (PLA, only in blends)

- Polyhydroxybutyrate (PHB)

- Bio-polyethylene (Bio-PE)

- Bio-polypropylene (Bio-PP)

According to current usage, "bio" stands for both "biobased" and "biodegradable". Biodegradable plastics from fossil sources, such as degradable polyesters, are therefore also referred to as bioplastics.

Biobased, non-biodegradable plastics also belong to the category of bioplastics. These are natural fibre-reinforced plastics such as hemp and flax fibres with polypropylene, polyethylene, polyethylene terephthalate or phenolic resin, as well as wood-plastic composites (WPC).

The latter are thermoplastically processable composites, e.g. made of polyethylene or polypropylene with up to 80 percent wood flour and additives. The production volume of these plastics in Europe has now grown to 12,000 tonnes per year in the construction and furniture industry alone. The European automotive industry uses another 50,000 tonnes annually.

From "thermoset bomber" to high-performance materials

The type of synthesis process determines the characteristics of the plastic. Depending on its physicochemical properties, the plastic is classified into one of three categories (independent of the raw material source):

- Thermoplastics are materials that soften when heated and harden again when the temperature is lowered. They can be melted down and reused several times. They include, for example, Plexiglas (spectacle frames), polyester (disposable bottles), PVC (pipes) or polyethylene (carrier bags).

- Elastomers are materials that deform elastically under both tensile and compressive stress and then return to their original shape when the force ends. Elastomers are used to make polyurethane (balls), rubber (rubber bands) or silicone (baking moulds).

- Thermosets are materials that remain hard even under the influence of temperature once they have taken their shape. Thermosets are found, for example, as Bakelite in pistol grips, as aminoplastics in household appliances or as epoxy resins in motor and glider sports. The cult car of the GDR, the Trabant, was also made of this plastic and went down in history as the "Duroplast Bomber".

Ultimately, the thermoset bomber was far ahead of its time, even if hardly anyone realised it at the time. Today, Formula 1 racing cars, luxury sports cars and even

normal cars are themselves plastic bombers, albeit made of higher-quality plastics.

SMEs shape the Austrian plastics industry

With a share of 47.5%, the plastics industry is an important part of the Austrian chemical industry (35.7% plastic goods and 11.8% plastics in primary forms).

Due to the small domestic market in Austria, most companies in the industry rely on an export strategy. About two-thirds of the total turnover is achieved in exports, with more than 80 % of the plastic goods being exported to other European countries.

In 2020, the sold production of plastics producers and processors was around 7.2 billion euros. In addition to plastic raw materials and plastic goods, additives are also produced in Austria.

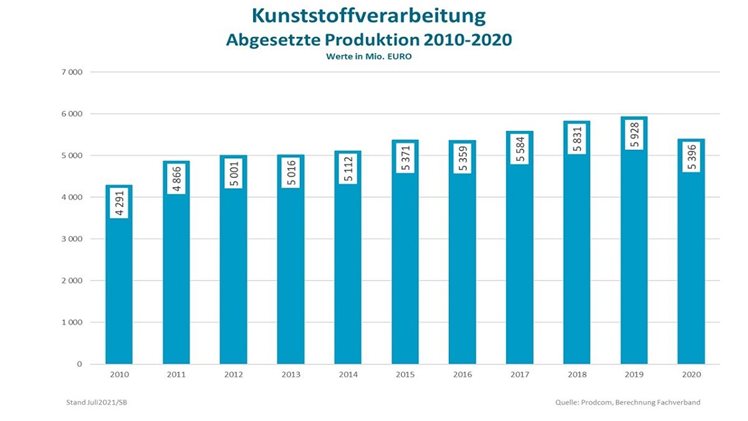

Plastics processing in Austria

The SME-dominated plastics processing sector in Austria comprises about 570 companies with an average of 56 employees and an annual turnover of 14 million euros. Only 5 % of the companies employ more than 250 people. Most of the production value and more than 50 % of the total 30,500 jobs are located in Lower and Upper Austria.

Every year, 1.1 million tonnes of polymers (thermosets and thermoplastics) are processed in Austria. Around 37% of the sector's turnover is accounted for by semi-finished products such as sheets, films, hoses and profiles, 16% by packaging materials, 13% by building materials and 34% by other plastic goods (2019).

The production sold in 2020 amounted to 5.4 billion euros. The export ratio is 33 % on average. Some companies are almost entirely geared to the export market.

Plastics production in Austria

On the procurement side, the plastics processors are contrasted by 18 raw plastics producers with an average turnover of 400 million euros. The largest plastics producer in Austria and number two in Europe is

Borealis AG. The company produces around 1 million tonnes of polyolefins in Schwechat. In 2020, Borealis achieved a global turnover of around 4.57 billion euros in the polyolefins business segment.

A significant share of the raw plastics produced is processed directly in companies in the consumer industries. For example, the food industry itself produces packaging, and the same applies to the production of parts for electrical appliances or cables in the electrical industry. Relevant customers are also the synthetic fibre and ski industries.

The sold production of plastics production amounted to about 1.8 billion euros in 2020. The majority of this was exported. The product portfolio includes the standard plastics polyethylene (PE), polypropylene (PP) and expanded polystyrene (EPS), resins for paints and adhesives, and other plastics.

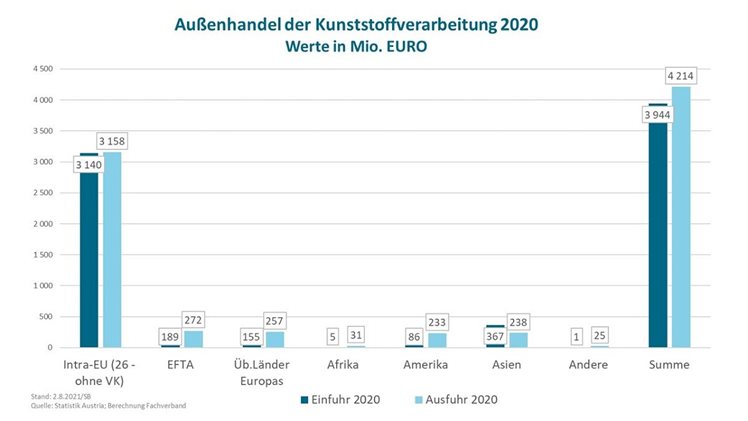

Foreign trade of plastics processing in Austria

The share of plastic goods in Austrian exports has been around 3 % for years - and thus slightly above the EU share of 2.5 % most recently. Export surpluses arise primarily in the areas of technical plastic goods and plastic packaging.

In 2020, plastic goods (from production and trade) worth about 4.2 billion euros were exported. The largest trading partner is Germany with more than a third of all exports, followed by France, Switzerland, Italy and the Czech Republic. For imports amounting to 3.9 billion euros, Germany also ranks first as the most important partner, followed by Italy and Switzerland.

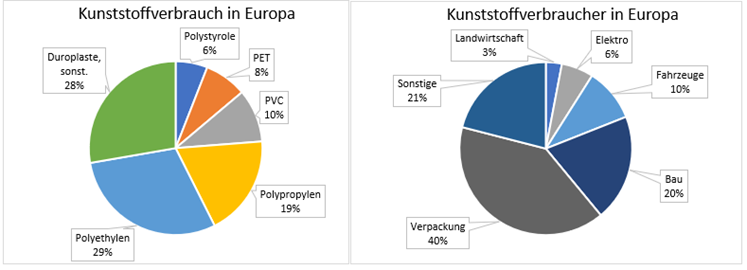

Current situation of the plastics industry in Europe

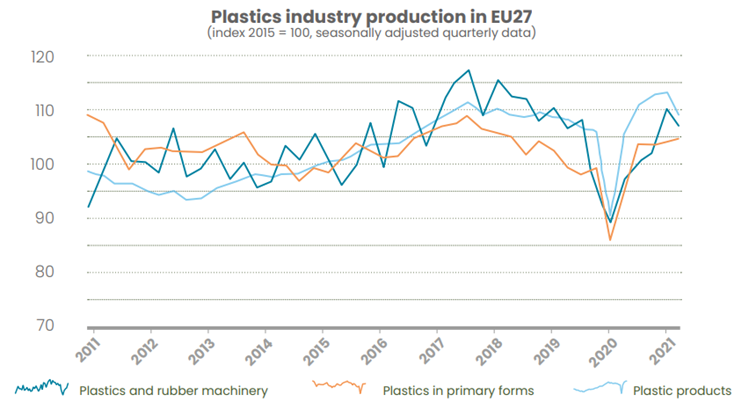

The main consumers of raw plastics in Europe are the packaging industry (40%), the construction industry (20%), the automotive industry (10%) and the electrical and electronics industry (6%). The recovery of European user industries, such as the automotive industry, but also the continued high demand for plastics in primary forms outside Europe had a positive impact on production in 2021.

Source: PlasticsEurope, UniCredit Research, percentages refer to 2018.

However, external effects such as problems in the global supply chain, bottlenecks in intermediate products and

rising energy prices continue to dampen production. For example, producer prices for plastics in primary forms rose sharply in 2021. The main reason was the 95% higher prices for naphtha in the EU compared to 2020. Energy prices, transport costs and costs for additives also increased.

As an energy-intensive sector, the plastics industry is particularly affected by the high energy prices. Even if there are no restrictions on energy supplies from Russia, energy prices are expected to remain high due to high uncertainties and the

impact of sanctions.

Source:

Plastics Europe, Plastics - the Facts 2021

Conclusion: Plastics industry

The plastics industry is a sector with a wide range of possibilities for the mass production of "tailor-made materials". Not least, the advantages of plastic products lie in areas such as lightweight construction, food durability, thermal insulation, energy efficiency, functional integration and much more. With the increasing use of sustainable plastics and the promotion of the circular economy, the ecological footprint of plastic products is also decreasing.

Related links/Sources:

Plastics Europe Quaterly Report Q4-2021

Bank Austria Branchenbericht Kunststoffverarbeitung 2020

Advantage Austria – Zahlen und Fakten Branche Chemie/Kunststoff

Plastics Europe, Plastics - the Facts 2021

AK Branchenreport, Kunststoffverarbeitendes Gewerbe 2021

Plastikmüll unerwünscht: Frachter verweigern Exporte (

orf.at Stand 19.04.2022)