Donauchem GmbH offers a wide range of additives for use in technical chemicals, products and production, partly under its own names such as DonSol, DonFoamex, DonPlex and under various chemical names.

In addition, our portfolio also includes numerous additives which we distribute exclusively for various producers on the Austrian market.

What are additives?

In the chemical industry, additives are auxiliary materials or additives that are added to products or preparations in order to achieve, improve or adjust specific properties.

The term additive is derived from the Latin additivum, which means to add or to add.

In order to achieve a positive effect during the production, storage or processing of products, formulations or preparations, or during or after the use phase, various additives are used. As a rule, these are contained in small quantities and usually finely distributed in the respective material.

Additives must be optimised for the application and can have either hydrophobic (in fuels, oils, non-polar systems) or hydrophilic (in aqueous solutions) character. Additives in solid form are also available for solid mixtures.

The following general properties characterise the various chemical additives:

- Specific effectiveness

- Low health hazard (especially for food additives)

- High efficiency

- High stability(s)

- Very good environmental compatibility

- No negative effects (on material, environment, people, etc.)

- Long-lasting specific effectiveness

The quantities of additives used must always be adapted to the product. There are no exact rules or application instructions. The proportion of additives should be kept as low as possible in order to avoid possible interactions or influences on other product properties.

What types of additives are there?

Additives can be used in a wide range of applications.

- Processing aids such as emulsifiers, thickeners/thickening agents, dispersing agents

- Drying agents (siccatives): used in lacquers and natural resins as well as plastics

- Wetting and dispersing agents: for lacquers and paints; for use in rinsing and cleaning agents

- Binding aids: e.g. hardeners or co-hardeners for lacquers and paints

- Solvents: thinners in various applications

- Antioxidants: varnishes, printing inks, dispersion paints

- Preservatives and biocides

- Defoamers: for all applications in aqueous media, for foam prevention; in paints and varnishes, during chemical syntheses, etc.

- Plasticisers: in plastics

- Aggregates for building materials

- Light stabilisers (UV absorbers, radical scavengers)

- Levelling agents

- Antistatic agents

- Flame retardants

- Fluxes: preparation of solder surfaces; glass production

- Pigments: Paints, lacquers, plastics

- Matting agents

- Corrosion inhibitors

- Blowing agents

- Functional fillers

- Hydrophobing agents

- etc.

Additives are special chemicals, which are usually characterised by higher prices, thus not only increase the material price of the manufactured material, but also significantly improve its value, service life and economic efficiency to the same extent. The use of additives is therefore characterised by many advantages.

Special applications of additives

Fuels

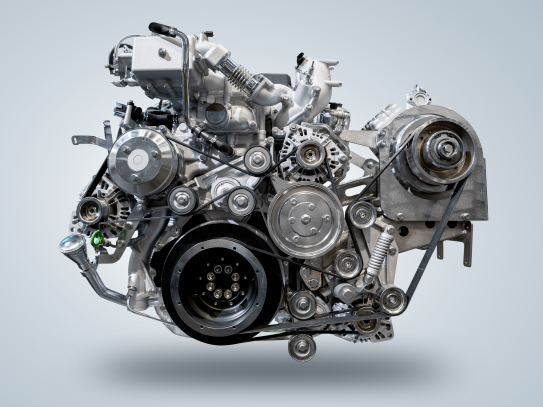

Various additives are added to fuels to strengthen or improve certain properties. Anti-knock additives are added to petrol to increase its anti-knock properties. Diesel fuel contains additives to improve its low-temperature properties.

Fig. Internal combustion engine

Lubricants and cooling lubricants

In addition to the base oil, they contain, among other things, corrosion inhibitors, defoamers, biocides, wear reducers, emulsifiers, antioxidants, dispersants and wetting agents as well as other modifiers, which are usually added to the base oil as a so-called additive package.

Fig. Use of lubricants

Coating materials (varnishes, paints, printing inks)

In addition to the price/performance ratio, the selection criteria for additives in this application are based exclusively on the mode of action and effectiveness. Here, one has to be particularly sensitive and precise and formulate accordingly.

For example, the use of surfactants can cause foam, while defoamers tend to form craters. Special attention must be paid to a balanced setting of the respective system.

Besides wetting agents and defoamers, the following substances are also used in coating systems: pigments, dyes, biocides, dispersants, co-solvents, flow aids, UV stabilisers and the like.

Fig. Paint processing

Plastics and rubber

Numerous additives are also used in the field of plastics and rubber, both in production and processing. For example: Antioxidants, radical scavengers, acid scavengers (PVC), anti-ageing agents (thermostability) such as stearates or carboxylates, light stabilisers (UV stabilisers), impact modifiers, pigments and fillers, optical brighteners, adhesion promoters, antistatics, blowing agents, etc.

Fig. Rubber processing

Building materials/concrete admixtures

Concrete admixtures are additives slurried in water and added to concrete to improve its mechanical, physical and chemical properties and durability. They influence the workability, the setting behaviour, the hardening and the durability of concrete.

Other additives are used in concrete as well as in other building materials (solid and liquid): superplasticisers, plasticisers, retarders and accelerators, air-entraining agents, thickeners, stabilisers and biocides.

Fig. Concrete mixer

The

Donauchem product portfolio includes a range of additives.

For further information or quotations,

please contact us.

www.donauchem.at

www.donauchem.at