Sodium lauryl ether sulphate is a classic among the mass surfactants, but still very well proven and contained in many products. As a supplement to our article on the general bottleneck situation on the surfactant market, we would like to briefly highlight the importance and current availability of this tried and tested surfactant.

Sodium lauryl ether sulphate: cleaner and foaming agent

Sodium lauryl ether sulphate is an anionic surfactant from the group of alkyl ether sulphates, which is characterised above all by its strong cleaning power and excellent foaming properties. Synonyms for the surfactant/wetting agent are sodium laureth sulphate (SLES) and sodium 2-(2-dodecyloxyethoxy)ethyl sulphate.

Specifically, SLES is the ethoxylated form of sodium lauryl sulphate. Due to the sulphate group, SLES has a negative charge that determines the hydrophilic (water-soluble) component of the molecule.

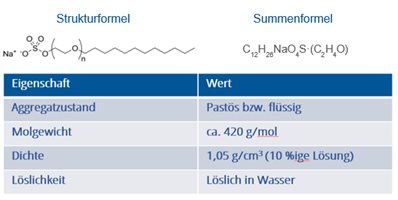

Fig. Structure, molecular formula, properties of sodium lauryl ether sulphate

The applications of SLES

Sodium lauryl ether sulphate is a strong oil and grease dissolving detergent and is therefore often used in detergent formulations. Due to its additional strong foaming property, SLES is one of the most important components of synthetic cosmetic and hygiene products. It is found as a surfactant in liquid soaps, shampoos and shower gels, but also as an emulsifier in toothpastes, creams, cosmetics, lotions and the like. In addition, sodium lauryl ether sulphate is also used in the production of foamed concrete, as a foaming agent and grease solvent.

The production of SLES

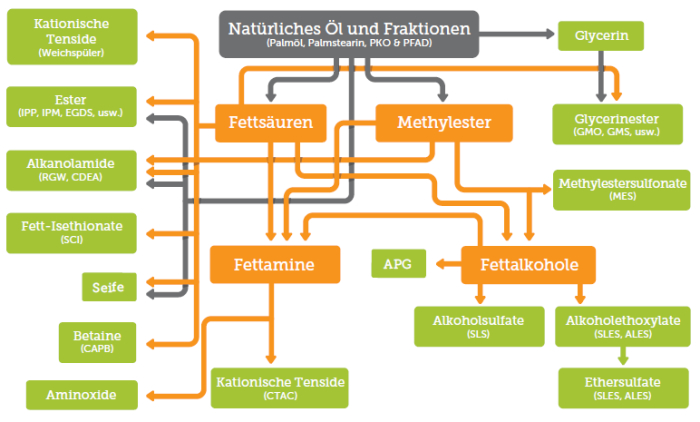

SLES is produced on the basis of lauryl alcohol (dodecanol), which in turn is obtained from vegetable lauric oils. Laurin oils can be extracted from palm kernel oils or coconut oil. Palm kernel oils account for about 80% of the fatty alcohols and surfactants produced from them, while the remaining 20% are attributed to coconut oil.

The manufacturing process is as follows:

- Dodecanol is obtained by hydrogenating the fatty acids and fatty acid esters from palm kernel and coconut oil and then working up the reaction mixture.

- SLES is produced by reacting dodecanol with ethylene oxide. The number of oxyethylene units is usually about 2.

- Sulphur trioxide is then used for sulphation.

- A by-product of this process is 1,4-dioxane, which is harmful to health. The end product with two oxyethylene units, sodium 2-(2-dodecyloxyethoxy)ethyl sulphate, is considered irritating to the skin and eyes.

Source:

RSPO Supply Chains

Current shortages in raw materials for SLES production

Currently, a general shortage of the most important raw materials for the production of surfactants can be observed in Europe. The following shortages are particularly relevant for the production of SLES:

1. Shortage of dodecanol or palm kernel oil

The shortage of palm kernel oil for the production of dodecanol is mainly due to the high demand in Asia, which means that less export volume is available for Europe. In addition, production in Malaysia, one of the most important palm kernel oil producing and exporting countries, has been curtailed due to the lockdown. According to the Malaysian Palm Oil Council (MPOC), only a slight increase in production is expected in the coming months.

Reduced transport capacities due to a persistent shortage of containers and ships as well as congested ports further aggravate the situation. Various blockades, such as the one now again in the world's fourth largest container port of Yantian (Guangdong province), further exacerbate the situation and will continue to affect supply chains until the end of the year.

2. Ethylene oxide bottleneck

Crude oil processing is still too low to produce the required quantities of petrochemicals. The available quantities of ethylene oxide are therefore still subject to shortages.

3. Bottleneck sulphuric acid

Sulphuric acid is essential for the sulphation of anionic surfactants such as SLES. However, this is also currently in severe shortage due to reduced crude oil processing, disrupted supply chains and other factors.

The delivery forms for SLES

Conventional delivery forms for SLES are aqueous preparations with a washing-active substance content of 70% (pasty) or 27%-28% (liquid). The corresponding Donauchem products are

DonSol SLES 27 and

DonSol SLES 70.

Another product in our portfolio is the alkaline surfactant

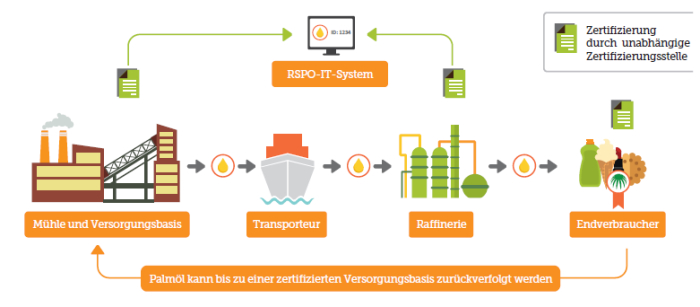

DonSol SLES A RSPO from sustainable cultivation. RSPO stands for "Roundtable on Sustainable Palm Oil". The cultivation of RSPO-certified, sustainable oil palm products is intended to help reduce the negative impact of oil palm cultivation on the local population and environment.

Quelle:

RSPO Supply Chains

Conclusion: Set up supply security

Hardly a month goes by without new events that put pressure on global supply chains and lead to considerable delays in deliveries. From today's perspective, a stabilisation of raw material supplies in Europe is not expected in many areas until the end of the year. Anionic surfactants such as SLES, which account for about 50% of the surfactant market, are currently also affected by a lack of availability. Therefore, make provisions in good time to avoid production bottlenecks.

If you have any questions about SLES or our surfactant portfolio in general,

please contact us.

www.donauchem.at

www.donauchem.at