The Pischelsdorf industrial park has a first-class company fire brigade. Seven men are on standby around the clock. Ing. Karl Hofbauer, plant manager of the activated carbon division, has led the team of about 80 firefighters as commander since 1996. In this article he reports on how the company fire brigade is organised, what happens in case of an alarm and what demands are made on fire fighters.

History: 35 years of the Donau Chemie AG company fire brigade, Pischelsdorf plant

The Donau Chemie company fire brigade has been in existence for 35 years. It existed on a voluntary basis for twenty years before it became officially required with the relocation of Donau Chem to Pischelsdorf and the construction of the AGRANA bioethanol plant in 2007. Since then, the company fire brigade has been subject to the provisions of the Lower Austrian Provincial Fire Brigade Act, which means that defined requirements must be met with regard to equipment, number of teams, training, equipment and special extinguishing agents.

The stand-by system: seven men on call 24/7

The operational readiness of the company fire brigade is ensured with a guaranteed minimum deployment strength of seven men at any time of day or night. The 80-man squad is made up of employees from the entire industrial park whose activities are suitable for rapid deployment. These include shift fitters and shift electricians, who, unlike employees in the control room of a plant, can quickly leave their workplace.

In terms of organisation, it is the companies' responsibility to ensure that the designated number of firefighters are on call on each shift. "Of course, the on-call system should not have any influence on shift cycles, holidays or sick leave replacements. That is why we need 80 men, so that we can provide seven men around the clock," explains Karl Hofbauer.

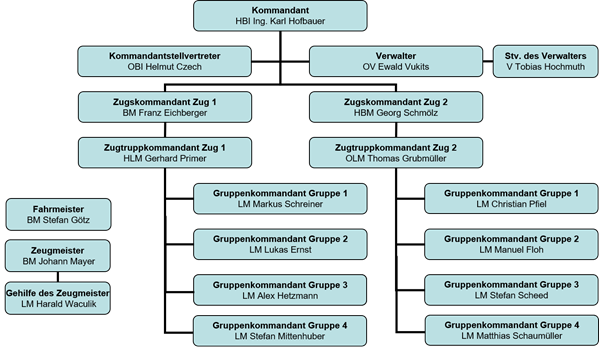

The organisational structure of the company fire brigade © Donau Chemie AG

Fire protection: company fire brigade and companies work closely together

In fire protection, a distinction is made between preventive and defensive fire protection. The company fire brigade is primarily responsible for fire prevention, while the company is responsible for fire prevention. In addition, the company fire brigade also provides support during external operations.

1. Pischelsdorf Industrial Park

Preventive fire protection includes measures to effectively prevent the outbreak and spread of a possible damaging fire. This area includes, among other things, the creation of fire protection regulations, the preparation of fire protection plans, the appointment of a fire protection and evacuation officer as well as an authorised person for the release of hot work.

Fire prevention, on the other hand, describes measures to fight and contain a fire that has already started. The area of operation of the company fire brigade for defensive fire protection covers all six chemical plants in the industrial park with currently about 650 employees. Among them are four accident-prone plants that are subject to the

Seveso-Regime and have to fulfil additional official requirements.

Chemical plants in the Pischelsdorf industrial park © Donau Chemie AG

However, the company fire brigade is also responsible for supporting tasks. One example is fire safety watches during dangerous activities such as cutting work near a gas pipeline or flammable liquids that cannot be removed.

Technical support is also part of the company fire brigade's remit. In a production facility,

for example, a respirator wearer is needed who can enter a room whose atmosphere has too little oxygen or is enriched with pollutants by wearing an ambient air-independent respirator or protective suit.

Wearing this equipment is very strenuous. Gas-tight protective suits, in particular, place high demands on physical fitness and only allow short periods of use of 20 to 25 minutes maximum. The crew is therefore tested for resilience and respiratory protection fitness by means of a performance test as part of the annual preventive medical check-up.

Breathing apparatus wearers in production © Donau Chemie AG

2. Pollutant base of the Tulln district

The Donau Chemie company fire brigade is the pollutant support point for the Tulln district and is thus responsible for fire operations, traffic accidents and technical damage situations involving chemicals, gases, explosives and corrosive or toxic substances in the region. "In an emergency, we support the local emergency services with our specially equipped emergency vehicle, our equipment and our team," says Karl Hofbauer.

3. TUIS: Transport Accident Information and Assistance System

Donau Chemie is a member of the

TUIS of the Austrian Chemical Industry Association (FCIO), which provides round-the-clock expertise and assistance in case of transport accidents involving chemicals. Currently, 38 companies in Austria belong to the TUIS system. TUIS is also part of the Western European assistance system

International Chemical Environment (ICE).

If an accident involving chemical products occurs on public transport routes, authorised bodies such as fire brigades, police or water authorities can request assistance from member companies at three assistance levels:

- Level 1: Technical advice by telephone

- Level 2: Advice by experts on site

- Level 3: Assistance by one or more company fire brigades on site with specialised equipment and/or personnel.

Most of the calls concern level 1, i.e. expert advice by telephone. At level 3, the Donau Chemie company fire brigade provides technical assistance with an emergency container in the event of leaking chlorine gas cylinders, for example. It is also used throughout Austria in the event of accidents involving sulphuric acid, as Donau Chemie is the only company in Austria that produces sulphuric acid and therefore has the necessary knowledge and special equipment.

Respiratory protection personnel in action © Donau Chemie AG

The alerting system: on the scene in five minutes

Three factory sirens and an additional fifty internal electronic sirens in the plants, workshops and office buildings ensure that employees are warned and evacuated in good time in the event of an emergency. There are six defined assembly points in the plant where evacuation can also take place department by department. Evacuation of the entire plant is rarely necessary, but is practised annually.

As soon as the sirens go off, all firefighters receive a blue-light text message in parallel, regardless of whether they are at the plant or at home. Via a smartphone app, they can confirm whether or not they will be called out. The firefighters on standby, on the other hand, have to be at the scene within five minutes.

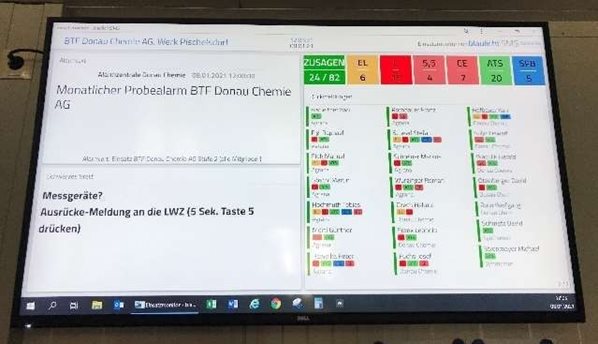

On the deployment monitor in the fire station, the assigned group commander then immediately sees how many respiratory protection personnel, C-drivers, skippers and other group commanders are participating in the deployment. Based on this, he decides whether to send out additional alerts.

The deployment monitor shows the commitments of the fire fighters and their deployment options © Donau Chemie AG

The fire alarm system: central control centre for all partner companies

In the Pischelsdorf industrial park, 2,700 automatic detectors (smoke, heat, flame) and 650 push-button detectors are installed, which are centrally linked in a modern, digital control system. "Reliable early fire detection and a powerful, fast company fire brigade prevent many a major fire," says Karl Hofbauer.

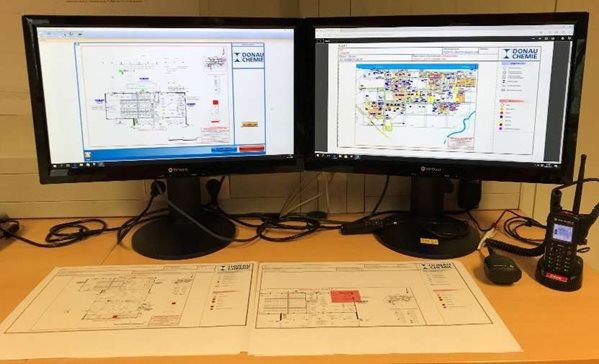

As soon as one of the fire alarm systems (BMA) goes off, the alarm printer in the fire station prints out an overview with fire protection plan, detailed plan and water supply plan. The group commander in charge thus has an immediate overview of the operation and can take appropriate measures as soon as he arrives.

In addition, cameras that automatically switch on in the event of an alarm provide information about the situation on site. This makes it possible to make an initial assessment of the situation at the scene of the fire while still at the fire station. If the smoke is black, for example, the volunteer fire brigades could also be alerted.

Of course, there are always false alarms, which the fire brigade calls "false alarms". For example, dust or fog generated by a leaking steam pipe can trigger a false alarm.

In case of an alarm, printouts with all relevant information are immediately available © Donau Chemie AG

The fire station: conversion to self-sufficient energy supply

To ensure the operational capability of the company fire brigade in the event of a prolonged power failure, the fire station is currently being equipped with a self-sufficient emergency power supply and emergency lighting. The vehicles are connected to so-called charge maintenance systems anyway.

The training: Chemical operations need comprehensive competence

Training with the company fire brigade requires physical fitness, but no special previous knowledge or experience. The main building blocks include basic training, ongoing drills and training, advanced courses and various special training. "All exercises, training and operations are counted as service time. This also results in some synergies with the voluntary fire brigade," Karl Hofbauer emphasises.

Basic training on the company premises together with the BTF of the Dürnrohr power plant © Donau Chemie AG

1. Basic training of the company fire brigade

Basic training takes about two years. It includes 122 hours of general fire brigade training and participation in at least six exercises and training courses per year to put what has been learned into practice. The training concludes with an examination that includes a theoretical and a practical component. Employees who are already active in the volunteer fire brigade do not have to complete this training. Overall, about 70 percent of firefighters are also involved in a volunteer fire brigade.

The individual modules of the general fire brigade training © Donau Chemie AG

2. Ongoing drills and training

In addition to the general basic training, monthly drills and training sessions (platoon drills) are held. In addition, each company is drilled at least once a year. In 2021, there were a total of 29 exercises, 15 of which were platoon exercises.

Exercise with chemical-resistant protective suits for operations with acids and alkalis © Donau Chemie AG

3. Courses and special training

An important part of the training is the continuation of courses in the fields of technology, tactics and leadership at the Lower Austrian Fire Brigade School in Tulln. Great importance is also attached to training in the field of hazardous substances, because the health of the firefighters during operations with hazardous substances has the highest priority at Donau Chemie.

"The volunteer fire brigades are well trained and equipped for fires and traffic accidents, but chemistry is always a special area. There is only one hazardous materials vehicle and crew in the whole district, because of course it is not only expensive, but also the education and training of the staff is very important," Karl Hofbauer explains.

In the context of special training, for example, various pollutant and fire scenarios such as leakages, boiler and gas fires are practised under real conditions with a hazardous materials and fire simulation system (GUBAS). Such special exercises are instructed and conducted by external specialists.

Training our team for a gas fire © Donau Chemie AG

4. Additional training fire brigade licence

The Donau Chemie company fire brigade attaches great importance to every firefighter being able to drive a fire engine. Those who only have a B driving licence must complete additional training in order to acquire the driving licence for emergency vehicles up to 5.5 tonnes (small fire-fighting vehicle, supply vehicle). The training and examination are carried out by a driving school. The driving licence obtained can, of course, also be used by the volunteer fire brigade.

5. Cooperation with the volunteer fire brigade

An important part of the training is the cooperation with the volunteer fire brigades, which takes the form of training and joint exercises. The exercises take place in the industrial park, but also externally, for example as part of a large-scale exercise with the seven volunteer fire brigades of the market town of Zwentendorf and the plant fire brigade of the Dürnrohr power plant.

First aid and extended fire-fighting assistance: fire extinguishers for every employee

In the industrial park there are 830 hand-held fire extinguishers and 65 wall hydrants for carrying out extinguishing measures before the fire brigade arrives. The extinguishing aids are checked every 2 years by the company fire brigade.

In the course of these maintenance activities, there is also an evacuation exercise and instruction of the

employees on the correct handling of the hand-held fire extinguishers.

Each employee is given the opportunity to extinguish a fire that is generated with the mobile, gas-heated fire simulation system.

Extinguishing aids © Donau Chemie AG

The vehicle fleet: Well prepared for emergencies

With a tank fire engine, small fire engine and supply vehicle, three standard fire engines are available, as well as a measurement service vehicle and a hazardous materials vehicle with protective clothing and hazardous materials equipment. The latter are special vehicles that are also frequently used in external operations to support local emergency forces and in TUIS operations. For the water supply, there are a total of 60 hydrants, four extinguishing wells, two extinguishing basins and, of course, the Danube.

The vehicle fleet of the company fire brigade includes a tank fire engine, a hazardous materials vehicle, a supply vehicle, a small fire engine and a measuring service vehicle (from left to right). © Donau Chemie AG

The equipment of the company fire brigade also includes various trailers and special equipment required for use in the chemical sector:

- Powder extinguishing trailer: The powder extinguishing system with 1,000 kg of extinguishing powder and quick-attack equipment is indispensable for gas fires.

- Extinguishing support trailer (LUA): For production halls, powerful mobile fans are needed to blow smoke free (volume flow 80,000 m³/h)). The standard ventilators of the volunteer fire brigade are best suited for clearing stairways or flats of smoke, but not for larger halls.

- Hazardous material trailer with forced air supply system: The forced air supply via the trailer makes it possible to supply the protective suit wearers with air for longer than with the normal breathing equipment. In addition, 6 more gas-tight protective suits are loaded.

- Alcohol-resistant foam agents: Flammable liquids that are miscible with water cannot be extinguished with conventional foam agents (e.g. methanol). This requires alcohol-resistant foaming agents that form a polymer layer and are correspondingly expensive. Donau Chemie stores 10,000 litres at the plant and also makes them available to the volunteer fire brigade for larger operations.

- Breathing air filling station: The rapid availability of filled breathing apparatus bottles is important during fire and hazardous materials operations.

- Chlorine gas emergency container: Chlorine gas is a toxic and corrosive hazardous substance. Leaking chlorine gas cylinders must therefore be recovered in a special container.

- Motorised barge: The motorised barge can be deployed quickly and has also been used successfully to assist in rescuing people on the Danube.

- Washing machine and dryer: The emergency clothing is washed, dried, impregnated and disinfected in the washing facility directly on site.

Pulverlöschanhänger und Löschunterstützungsanhänger der Betriebsfeuerwehr © Donau Chemie AG

Conclusion: Pischelsdorf industrial park fire brigade

Operational fire protection in chemical companies places high demands on the company fire brigade. Thanks to the support of the management and the high level of commitment of the team, the Donau Chemie company fire brigade is in a very good position. From this position, it will also succeed in preventing major fires and incidents of damage in the future.

Personal details:

Karl Hofbauer is the plant manager of the activated carbon division and has been the fire brigade commander of the plant fire brigade at the Pischelsdorf industrial park since 1996. In addition, he is a representative of the company fire brigades in the chemical and electricity sector in the company fire brigade committee of the Lower Austrian Fire Brigade Association. He is also chairman of the TUIS working group in the Federation of Austrian Industries (FCIO).

www.donauchem.at

www.donauchem.at