Surfactants are among the few chemical compounds that are used in Western Europe in a total quantity of about 2.5 million tonnes annually for a wide variety of applications. Currently, however, the supply of raw materials for natural and synthetic surfactants is coming under increasing pressure due to bottlenecks in the most important raw material sources for surfactant synthesis. In a brief overview, we show which raw materials are affected and where the causes lie.

Surfactants and their raw material base

The function of surfactants is to reduce the surface tension of a liquid or the interfacial tension between two phases and to enable the formation of dispersions or to act as solubilisers. The special molecular structure of surfactants creates the conditions for this:

- Surfactants are compounds whose molecules contain a hydrophilic (polar) molecular part and a hydrophobic (non-polar) molecular part.

- The head is water-loving (hydrophilic), while the rest is water-repellent (hydrophobic) and fat-loving (lipophilic).

- In an aqueous phase, the hydrophobic ends always migrate to where the water borders on another substance (e.g. oil, air, solids). The water-loving heads point into the aqueous phase.

Fig.Surfactant molecule

The various surfactants differ only slightly in the hydrophobic (fat-loving) part of the molecule. In the hydrophilic (water-loving) part of the molecule, on the other hand, there are very clear differences, as the polar part can have different structures:

- For the hydrophilic molecule part, anionic residues (negatively charged), non-ionic (uncharged), cationic (positively charged) or amphoteric residues (simultaneously negatively and positively charged) are used.

- The hydrophobic part of the molecule is always a hydrocarbon residue that can be produced from renewable (plant, animal) or fossil (petrochemical) raw materials.

With regard to the raw material sources used, surfactants can thus be divided into three categories:

- Surfactants that are produced exclusively from renewable raw materials.

- Surfactants that are produced exclusively from petrochemical raw materials.

- Surfactants that contain components based on both renewable and petrochemical raw materials.

The distinction between natural and synthetic surfactants, however, is not simple and in some cases not even meaningful, since even for the production of surfactants based on naturally renewable raw materials, additional chemistry is needed for further processing, which comes from other sources.

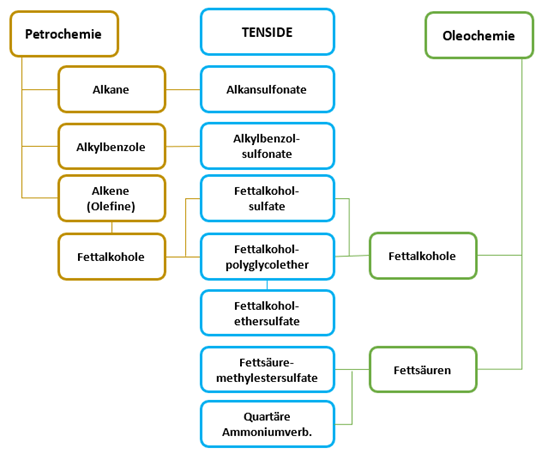

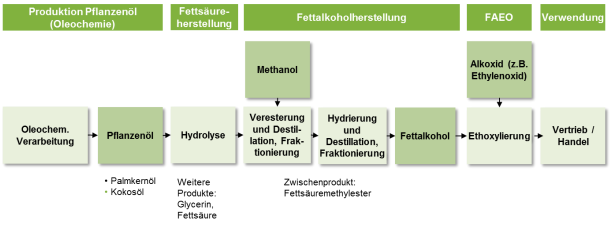

Petrochemical and oleochemical synthesis routes for surfactants are as follows:

Shortage of natural raw materials for surfactants

Natural surfactants are those made from animal and vegetable fats or sugars. The most important fatty acid for the production of surfactants is lauric acid. The fatty acid composition of coconut and palm kernel oils consists of 40 to 53% lauric acid. These oils are therefore also called lauric oils and are mainly used for surfactant production. For example, the surfactants used in detergents and cleaning agents are based on about 80% palm kernel oil and 20% coconut oil. Tall oil, a by-product of pulp production, is also used in the manufacture of surfactants.

1. bottleneck palm kernel oil

Palm kernel oil has the greatest overall economic importance for surfactant production from renewable raw materials. Palm oil, which is obtained from the pulp of palm fruits, is very low in lauric acids and plays only a very minor role as a raw material source for surfactant production.

The main producing countries for palm kernel oil are Indonesia and Malaysia, whose market shares in the export market were just under 60 and 25 per cent respectively in 2019.

The current shortage of palm kernel oil is primarily due to the following factors:

- High demand: Although palm oil or palm kernel oil would in principle be available in sufficient quantities in Asia, demand is currently so high that not enough quantities are being exported. The reason for this is that an excessive amount of palm kernel oil is being bought in Asia and other overseas markets in order to avoid any production bottlenecks in the future.

- Lockdown Malaysia: A resurgence of Covid-19 infections in Malaysia is exacerbating labour shortages and curbing palm oil production. The Southeast Asian country has already lost 20-30% of planned production due to the pandemic. The imposed extension of the lockdown until 28 June 2021 puts additional pressure on available export volumes.

- Supply chain disruptions: Another limiting factor is the still limited transport capacities due to the lack of containers, fully booked freighters, congested ports and various blockades. Currently, a new traffic jam is looming that could assume much larger proportions than in the Suez Canal. Due to stricter anti-corona measures in the Chinese province of Guangdong, there have been severe restrictions on shipping traffic in the container port of Yantian since mid-June. The port is one of the largest hubs for container traffic worldwide.

Source:

FNR, Market Analysis Renewable Raw Materials - Volume 34

2. bottleneck in sugar surfactants

Only renewable raw materials are used for the industrial production of sugar surfactants. The hydrophilic component of the surfactant molecule is synthesised from starch and sugar (wheat, maize, potatoes, sugar beet, sugar cane). Fatty alcohols or fatty acids, usually obtained from palm kernel oil, act as the hydrophobic component. Alkyl polyglycosides are produced, for example, from hexoses or pentoses and fatty alcohols.

The scarce availability of palm kernel oil and raw materials for the production of fatty alcohols and fatty acids thus also affects the availability of sugar surfactants.

Shortage of raw materials for synthetic surfactants

Synthetic surfactants are produced from petrochemicals and derivatives synthesised from them. Alkanes, alkylbenzenes, olefins and fatty alcohols, for example, are converted to secondary alkane sulfonates (SAS), alkyl benzene sulfonates (ABS) and to corresponding surfactants based on fatty alcohols. The causes of the raw material shortage are similar to those for surfactants based on natural raw materials:

Basic chemicals from the refinery process that are important for surfactant production, such as alkanes, alkylbenzenes or olefins, are in short supply due to the reduced output of ethylene oxide and propylene oxide. The same applies to petrochemicals such as glycols, glycol ethers or methanol. Similarly, the shortage of sulphuric acid and phosphoric acid affects the production of synthetic surfactants.

Conclusion: Take precautions in good time

Surfactants cannot be produced without petrochemicals and natural fats and oils. In addition to fats, other chemicals are used, depending on the synthesis route or the desired surfactant. Due to the unfavourable coincidence of bottlenecks in the most important raw materials, including sulphuric acid, the production of anionic surfactants in particular, which are used in the manufacture of household and personal care products, could become critical. Therefore, take these bottlenecks into account in your planning and make provisions in good time!

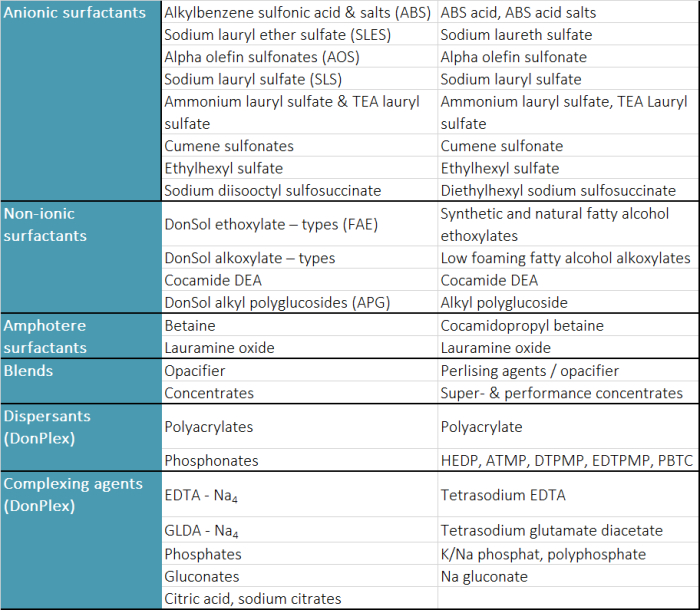

Finally, we would like to present the most important surfactant products of the Donauchem portfolio. You will find further products in our portfolio for commodities. If you are interested in special products other than those listed here, please contact us.

www.donauchem.at

www.donauchem.at