The chemical industry is one of the big key industries in the implementation of the Green Deal. Above all, green tech technologies such as batteries, solar panels, wind turbines, hydrogen or building insulation depend on the innovative power of chemical companies. How the decarbonisation of the chemical industry can be achieved, which challenges have to be overcome on this path and how realistic the ambitious climate targets currently are, more on this in this article.

Chemical industry in third place in EU comparison

Austria wants to achieve complete climate neutrality within the chemical industry by 2050. Already today, domestic chemical companies are among the pioneers in climate-friendly production in an international comparison. The industry is already making a significant contribution to decarbonisation through fuel-saving lightweight materials for cars or energy-saving thermal insulation for buildings.

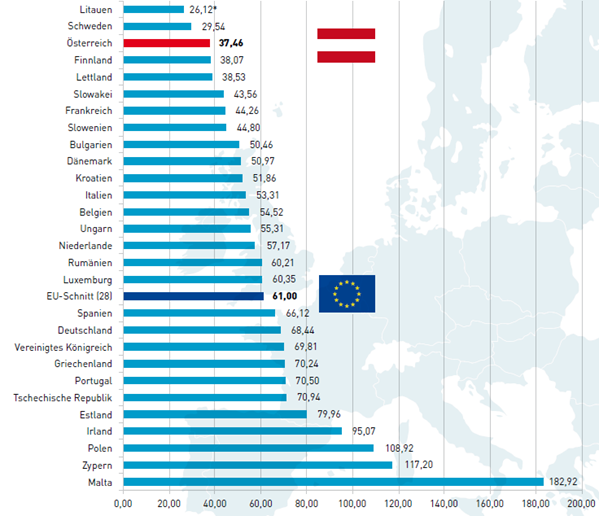

The industry is also doing well in terms of emissions. In an EU comparison, Austria's chemical industry ranks third (source:

study by the Institute for Industrial Ecology). With the release of only 37.46 tonnes of CO

2 per terajoule (TJ), the greenhouse gas pollution is about 60 per cent lower than the EU average (61 tonnes CO

2/TJ).

Figure:

CO2 consumption in tonnes per terajoule, FCIO

Impact of decarbonisation on the chemical industry

The chemical industry accounts for about 9.5 per cent of man-made global CO2 emissions. More than half of this is due to the direct use of fossil hydrocarbons as raw materials, while the other half serves as energy suppliers for the industry.

High dependence on fossil fuels

The energy factor accounts for up to 75 per cent of production costs in the manufacture of various products. Heating and cooling in chemical processes are currently still predominantly dependent on fossil fuels, for example in the form of gas-fired cogeneration. In contrast, a sustainable form would be a steam-powered, CO2-neutral heat cycle, as has already been implemented in the Pischelsdorf Industrial Park.

No oil - no petrochemicals

If, in the course of the energy transition, crude oil is no longer processed in refineries, there will clearly be a lack of basic products such as ethylene and propylene as well as all the downstream products that are so important for all of us and for all of humanity (see chemical/refinery flowchart). The result will be extremely high energy costs and increasing shortages - not only of chemical raw materials, but also of their downstream products, right through to everyday products.

So where will the chemical raw materials and the necessary energy come from if we completely abandon the use of fossil raw materials?

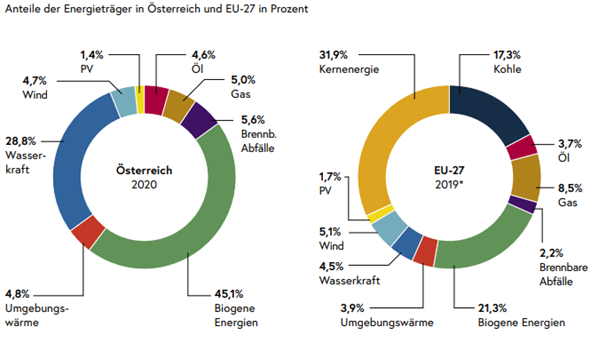

Gross domestic consumption in comparison. In Austria, the share of renewable energy sources in gross domestic consumption was 32.8 percent in 2020. This should rise to almost 100 percent by 2040.

Source:

Energy in Austria, 2021

Decarbonisation requires competitive electricity prices

Abandoning fossil energy sources means that much more cheap energy from alternative sources is needed. We are talking about three to five times the energy needed for the electrification of chemical processes. For the production of raw materials from green hydrogen, even eight to eleven times as much renewable energy is needed.

Alternative energy has lower energy content

The high energy demand in the course of decarbonisation will not be significantly improved by technological innovations either. This is because carbon dioxide, water and air have a lower energy content than natural gas, crude oil or coal - and are therefore poorer raw materials for energy production. Processes based on these raw materials are thus much more energy-intensive than those based on crude oil and natural gas.

60 hydropower plants for additional green power generation

In an FCIO study published in 2018, experts assume an additional demand for green electricity of around 60 TWh. This corresponds to 60 hydropower plants on the scale of the Freudenau power plant or Austria's electricity demand in one year. However, a sensible circular economy could halve this demand to 30 TWh, according to the results of the FCIO follow-up study.

However, the construction of alternative power generators alone falls short. Currently, Austria still lacks the infrastructure and grids to distribute green electricity to where it is needed. Only a holistic view of the energy transition can ultimately be successful. In this sense, of course, other industrial sectors such as housing and road construction must also set corresponding goals.

Primary energy production in comparison. Internationally, Austria's share of total EU primary energy production is 2.0%, of renewable energy production 4.6%. Source: Energy Austria 2021

Recycling and technology mix for CO2 neutral chemistry

According to the FCIO follow-up study, great potentials for decarbonisation in chemical production would lie in the use of

renewable hydrogen, the use of bio- and waste-based raw materials and, above all, in a massive push for plastics recycling. In order to be able to use the potentials of the circular economy, however, the legal recognition of plastics recycling as a climate protection measure as well as the legal equalisation of chemical recycling is necessary.

1. reduction of electricity demand through technology mix

The industry could obtain its carbon from CO

2 waste gases and biomass, obtain the hydrogen it needs from water by means of electrolysis, and generate steam by means of electricity generation. This technology mix could save up to 2.4 million tonnes of CO

2 annually in Austria by 2040 and halve the additional energy required from 60 to 30 TWh.

The use of renewable hydrogen in particular plays a significant role in this. For example, ethylene or propylene for the production of plastics could be produced from a mixture of CO

2 and renewable hydrogen. The CO

2 required for this can be captured from industrial processes or power plant exhaust gases.

As part of a

promising project, several domestic companies are already working on the large-scale use of CO

2 as a resource for the production of olefins, fuels and high-quality plastics.

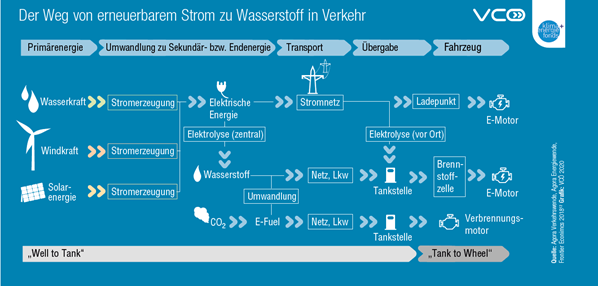

Graphic: Production of renewable hydrogen using the example of transport ©

VCÖ

2. Bio-based raw materials

The increased use of bio-based raw materials in the production of chemical substances represents another important component of climate-neutral production. However, the issue of

land competition, especially with regard to food production, must be taken into account, which is becoming increasingly relevant in Austria.

The global infrastructure for the final utilisation or composting of biobased plastics is also still needed. For this, certain temperatures and oxygen contents are necessary, which are not given in a classic landfill. If disposed of incorrectly, bioplastics decompose very slowly and produce the greenhouse gas methane, which is even more harmful than CO

2.

Asia is whistling at the decarbonisation of industry

The countries of the EU, and thus to a small extent Austria's chemical industry, contribute only about 10 per cent to global greenhouse gas emissions. The trend is already downwards - mainly due to the voluntary advance contributions of individual countries, industries or sectors.

In the global context, however, the EU's unilateral climate policy will not contribute much to making our world a better place to live in again. The three largest polluters alone, China, the USA and India, are now responsible for slightly more than half of global CO

2 emissions.

China in particular is massively slowing down the EU in terms of climate policy. According to the

Global Energy Monitor, new coal-fired power plants with a capacity of 38.4 gigawatts went into operation in 2020 - that is three times as much as the entire rest of the world put together! More than 600 additional coal-fired power plants are planned in China, India, Indonesia, Japan and Vietnam. In total, they are to generate 300 gigawatts of energy - the equivalent of Japan's entire generation capacity.

Coal-fired power plants should actually soon be a thing of the past.

Who should bear the gigantic costs of the energy transition?

Under these general conditions, the energy transition in Europe will place a heavy burden on entire industries, but will not noticeably reduce global CO

2 emissions. To become climate-neutral by 2050, the chemical industry would have to invest around 580 million euros annually. At the same time, higher production and network infrastructure costs are to be expected, which would massively impair the competitiveness of Austria's internationally oriented chemical companies.

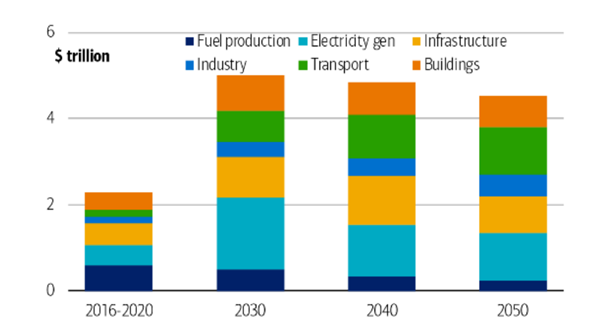

The

Bank of America (BofA) Global Research Report also recently made waves with a calculation of the possible costs for the implementation of the measures and goals of climate change - and they are gigantic:

150 trillion US dollars in new capital investments would be necessary to achieve a "net zero" world over 30 years. This would mean annual investments of about 5 trillion US dollars - twice the current global GDP. Who is going to pay these enormous sums? Private investors probably won't be.

Source:

„Transwarming” World: Net Zero Primer, B of A Global Research

Energy crisis: The end of the energy transition?

So while the energy transition has just begun in the EU and other countries are massively expanding their fossil energy production, Europe is in the midst of an unprecedented energy crisis. In the meantime, the price increases have not only driven some energy suppliers into bankruptcy, but have also led to

considerable production cutbacks in the chemical industry as well as other energy-intensive sectors.

Europe has apparently failed to secure energy supply through renewable energy before natural gas production fields, nuclear power plants and coal factories were closed. The phase-out of fossil fuels, the forced shutdown of all nuclear power plants (in Germany) is in contrast to the increasing demand for electricity due to the energy transition (electric cars, heat pumps, etc.).

From the current perspective, the energy supply situation in Europe will come to a head and cause electricity prices to skyrocket. If the EU does not take countermeasures, the acceptance of new climate protection measures will continue to dwindle - which in turn will jeopardise the Green Deal.

Europe needs a balance between green deal and fossil deal

The decarbonisation of industry cannot be solved by European countries acting alone. What is needed is not an Austrian, not a Europe-wide, but a global turnaround and a reversal of long-established trends. The challenge must be to find a reasonable balance between "green deal" and "fossil deal".

In order to be able to guarantee energy security, however, some changes would have to be made to Europe-wide industrial policy:

- Capping/limiting green electricity levies to limit energy costs for companies.

- Bringing renewable energies to market maturity.

- Green electricity support systems.

- Grid expansion and modernisation of energy infrastructure. The EU electricity grid in its current form does not meet the requirements of our time.

- Industrial self-generation of electricity as a contribution to security of energy supply.

- Increased use of biomass.

Large companies and multinationals in the chemical industry such as

BASF, DOW, Shell, ExxonMobil, Chevron are already working on making their companies fit for the future and also climate neutral. Optimistically, however, this will only become a reality from 2050 onwards.

Conclusion: Decarbonisation of the chemical industry

The chemical industry plays an important and leading role on the path to climate neutrality. On the basis of a circular economy in combination with appropriate technologies, decarbonisation of the chemical industry can certainly be achieved in Austria by 2050. However, this requires suitable legal framework conditions, investment subsidies and, above all, cheap electricity from alternative sources. At the same time, it is important not to lose sight of the balance in order to remain competitive in the global market.

www.donauchem.at

Sources and collection of further information:

Perspektiven zur Dekarbonisierung der chemischen Industrie

www.donauchem.at

Sources and collection of further information:

Perspektiven zur Dekarbonisierung der chemischen Industrie, Institut für industrielle Ökologie (2018)

Die chemische Industrie auf dem Weg zur Klimaneutralität, Institut für industrielle Ökologie (2020)

Integration erneuerbarer Energien durch Sektorkopplung: Analyse zu technischen Sektorkopplungsoptionen, Umweltbundesamt (2019)

Net Zero by 2050: A Roadmap for the Global Energy Sector (2021)

Global Research Report „Transwarming World“ - Net Zero Primer - Bank of America (2021)

Energie in Österreich - Zahlen, Daten, Fakten - Bundesministerium für Klimaschutz, Umwelt, Energie, Mobilität, Innovation und Technologie (2021)

climApro:Factsheet Potenzialanalyse veränderter Produktionsstrukturen in der österreichischen chemischen Industrie für globalen Klimaschutz und ihre monetären Auswirkungen - FCIO