The use of renewable raw materials in carbon-based chemistry is not new. A large number of industrial products are already made from them today. The most important chemical substance classes that can be produced in large quantities from renewable raw materials and used in polymer chemistry are cellulose, fats and oils, lignin, sugars and terpenes. In the following, we give a general overview of the bioeconomy and go into more detail on the groups of substances mentioned.

What are renewable resources?

Renewable raw materials, or NawaRo for short, are organic raw materials from agriculture, forestry, aquaculture or microbial production that, in contrast to fossil raw materials, renew themselves in manageable periods of time. They are used in non-food and come from targeted cultivation or are available as residual or waste materials.

In addition to the term "renewables", there is also the term "biomass", which is often used synonymously. In order to exclude the use of biomass as food and animal feed, it is referred to as industrial biomass.

Renewable raw materials include all living organisms and can therefore be of both plant and animal origin. Slaughterhouses, for example, produce large quantities of beef tallow, which is less suitable for food production but can be used to make soaps.

Why are renewable raw materials gaining in importance?

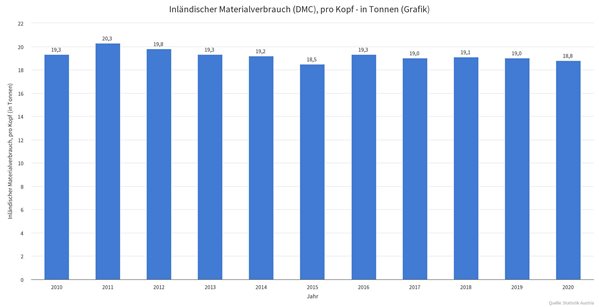

Austria has a high consumption of raw materials in international comparison. According to national data, domestic material consumption (biomass, metallic ores, non-metallic minerals, fossil energy sources) is around 19t/capita, which is significantly higher than the EU-28 average of around 14t/capita.

In terms of the

Austrian bioeconomy strategy and the implementation of the 2030 Agenda and its global Sustainable Development Goals (SDGs), a reduction of this per capita consumption and a stronger focus on renewable raw materials are necessary.

Since the chemical industry will increasingly obtain building blocks for organic syntheses from renewable raw materials in the future, their share is likely to increase significantly in the future.

Figure 1: Material consumption in Austria per capita in tonnes, taken from 1

What types of renewable raw materials are there?

The range of renewable raw materials that can be used industrially is very extensive. Basically, raw materials are differentiated according to primary and secondary constituents.

1. Primary ingredients of renewable raw materials

Primary ingredients are substances that occur in nature in large quantities. They ensure the structure and stability of plants and animals, but also serve as energy reserves. The sugar beet, for example, stores sugar reserves in its root, which it needs for reproduction. Some typical raw materials in this category are listed in the table below.

Figure 2: Primary ingredients of renewable raw materials, adapted from

2

2. Secondary ingredients of renewable raw materials

In addition to the primary ingredients, renewable raw materials also contain secondary ingredients, although these are present in much smaller quantities. This category includes, for example, odorants and colourants that serve plants to deter predators or attract insects for pollination. Further typical examples are shown in the table below.

Figure 3: Secondary ingredients of renewable raw materials, adapted from

2

Biobased industry means cascading use

The potential uses of renewable raw materials are very broad. They are used as raw materials in industry or as energy sources in a wide variety of areas:

- material use: raw material for chemical base materials, plastics or other bio-based products such as insulating materials, lubricants, paper and cardboard, medicines, cosmetics, dyes, textile fibres and much more.

- energy recovery: raw material for the production of heat, electricity and/or fuels (biofuels, biogas, biomass).

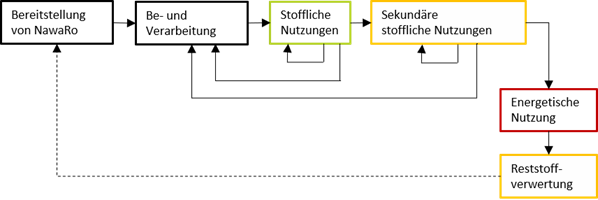

The goal of the biobased industry is the material and energetic utilisation within a "utilisation cascade". This means making the best possible use of all the components of the raw material in several cycles and only at the end of their (multiple) use to feed them into energy recovery.

The solution word in the biobased industry is cascading use. In view of the limited availability of biomass, multiple use of resources is inevitable.

Hubert Culik, Chairman of the Federation of Chemical Industries (FCIO)

The CO2 produced during combustion can subsequently be synthesised by plants through the photosynthesis of carbohydrates from carbon dioxide and water, releasing oxygen to form new biomass. It therefore makes sense to use biomass in a cascade, i.e. first materially and then energetically, if this is economically viable:

- material use: The renewable raw materials first reach the material use via various treatment and processing processes. At the end of their useful life, products can be reused for the same material use or recycled by reprocessing.

- Secondary material use: When a product reaches the end of its service life, it can sometimes serve as the starting point for a secondary material use. The more often a raw material is recycled, the higher the value added generated.

- Energy use: Since losses occur with every conversion, the recyclability of renewable raw materials is limited. Therefore, if further use is no longer economically or ecologically advantageous, the end of this utilisation cascade is the thermal utilisation of the biogenic material.

Figure 4: Cascading use of renewable raw materials, adapted from

3

Nature - the perfect chemical factory

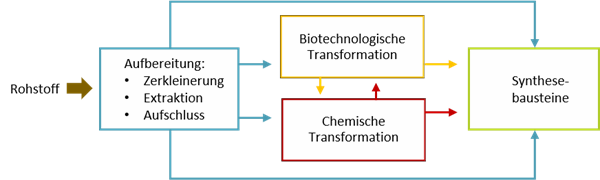

From a biotechnological point of view, renewable raw materials contain a synthesis input from nature that can be used in different ways depending on the raw material. Thus, ingredients from renewable raw materials can either be used directly or they have to be converted into suitable raw materials, so-called platform chemicals, with the help of various processes.

Platform chemicals are basic chemical substances that are needed for the production of other basic chemicals. Subsequent chemical processes then produce a variety of industrial products such as plastics, dyes, pharmaceuticals or raw materials for paints.

In general, the following basic scheme applies to the processing and conversion of renewable raw materials:

Figure 5: Processing and conversion of renewable raw materials, adapted from

3

The renewable raw materials are first mechanically crushed in mills and/or isolated in the desired purity through digestion processes or extractions. They can then be used in various ways:

- Direct use: the raw materials are only prepared and purified so that they can then be used directly as synthesis building blocks (such as sucrose from sugar beet).

- Chemical transformation: The raw materials are chemically transformed into the desired synthesis building block (such as hydrolytic reactions to split starch into smaller carbohydrate fragments).

- Biotechnological transformation: the raw materials are biotechnologically converted into the desired synthesis building block (such as the enzymatic cleavage of polysaccharides into individual sugar molecules).

Biotechnological and chemical processes can also be used in combination.

Cellulose: From paper to bioethanol

Cellulose is the most common and economically important biopolymer in nature. The renewable raw material is mainly needed in the paper and pulp industry, but is also often used in modified form as a regenerate and derivative. In addition, lignosulphonates, bioethanols and natural fibres obtained from cellulose are important raw materials.

1. Cellulose in paper and pulp production

The most important components of wood are cellulose, hemicelluloses (polyoses) and lignin. In smaller quantities, ingredients such as resins, waxes and terpenes are found. In order to prepare the wood for paper and pulp production, the cellulose fibres must be separated from the hemicelluloses and lignin, the cementing substance of the wood, in a chemical pulping process.

In most pulp mills, the acid

sulphate process (Kraft digestion) is used for the separation process. The advantage of this process is the high tensile strength of the pulp produced and the possibility of using woody plants such as reeds. The most important by-product in the sulphate liquor (black liquor) is tall oil fatty acids, which are used for the same purposes as fatty acids from other sources.

The basic

sulphite process is used for the production of high-quality pulp products. The pulp produced in this way is not as tear-resistant, but it is more suitable for the production of high-quality paper grades and special applications. The most important by-product from the sulphite process is lignosulphonates.

Besides the extraction of individual value products from by-products, lignocellulosic biorefineries offer the most promising prospects for replacing fossil raw materials. The

Lenzing Group's biorefinery model serves as a successful example.

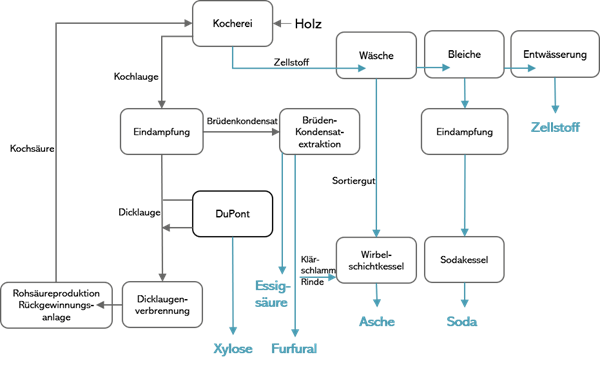

Figure 6: Lenzing biorefinery process, adapted from

4

2. Regenerated cellulose and cellulose derivatives

In addition to the direct use of cellulose in the paper and pulp industry, cellulose is used as chemical pulp for the production of cellulose-based polymer materials (cellulose derivatives and regenerates). Due to their natural origin in distinction to petrochemical polymers, these are increasingly gaining economic importance:

- Cellulose regenerates are mainly used for the production of various fibres such as viscose or films such as cellophane.

- Cellulose ethers (derivative) are used, among other things, as film formers, adhesives, protective colloids, stabilisers, washing and textile auxiliaries and thickeners.

- Cellulose esters (derivatives) are used, among other things, for the production of nitro varnishes and adhesives (cellulose nitrate) or for the production of textile fibres, films or switch buttons and lights in the automotive industry (cellulose acetate).

3. Lignin and lignosulphonates

Synthetic vanillin is produced on a large scale from lignin. In this way, about three kilogrammes of vanillin can be produced from one tonne of wood. Mixtures of lignin with other natural fibres such as flax or hemp are also processed into biodegradable fibre composites.

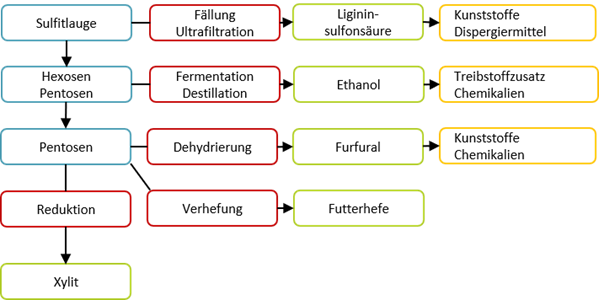

However, the most important material use of lignin is based on the use of lignin sulphonates, which are obtained from sulphite lye with the help of chemical-technical processes. Furthermore, valuable chemicals such as ethanol, xylitol, feed yeast or furfural can be isolated from the sugars dissolved in the sulphite liquor (monosaccharides: hexoses, pentoses).

Lignosulfonates are used as binders, dispersants, emulsifiers and sequestering agents in a variety of industrial applications. In addition to these main applications, they are used as raw materials for the production of chemicals.

Figure 7: By-products from the sulphite process, adapted from

4

4. Natural fibres

In addition to the traditional use of long fibres (textiles, ropes, nets, twine, canvas), new areas of application for short fibres have been developed in recent years:

- Building materials (plaster material, pressboard, roofing material, insulation).

- Natural fibre-reinforced composites (automotive trim, canoes, suitcases)

- Moulded parts or friction linings (for the automotive industry)

- Paper (wet-strength paper, banknotes, cigarette paper, filter material)

- Mulch material, plant propagation cups, fleeces

- Filter materials

Compared to glass fibres and rock wool, natural fibres are more suitable for insulation materials, for example, because they are lighter in weight and easier to process and dispose of.

5. Sugar

Hemicelluloses and celluloses can be converted into glucose, which can be used as a substitute for conventional glucose as a fermentation raw material.

6. Wood-based bioethanol

Waste liquors from sulphite digestion contain significant amounts of xylose (wood sugar) in addition to liginsulphonates, which can be used for the production of lignocellulosic ethanol. Vegetable waste materials such as straw are also suitable for its production.

The world's largest wood-based bioethanol plant has been operated by the Hallein-based cellulose factory

AustroCel since the beginning of 2021. In its in-house biorefinery, the company utilises all the components of the wood. Second-generation bioethanol is produced from wood sugar, which can be added to petrol as an "advanced biofuel".

The Hallein bioethanol plant is the world's largest wood-based bioethanol plant © AustroCel

Starch: Versatile in use

After cellulose, starch is the most important renewable raw material. Industrial starch production is mainly from maize, wheat, potatoes, rice and manioc. Because of its ability to bind and thicken, starch is increasingly used today in the non-food sector.

The main areas of application are in the manufacture of paper and corrugated cardboard and in biotechnology as a fermentable substrate for the production of various platform chemicals. Starch is becoming increasingly important as a raw material for the production of

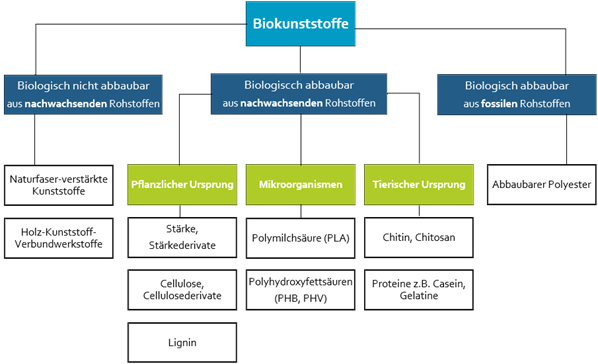

bioplastics.

- Paper and cardboard production: Starch improves technical properties (e.g. increasing paper strength, binding and smoothing paper, preventing ink from running, gluing corrugated cardboard).

- Biotechnological raw material: Starch serves as a fermentation base for microorganisms whose metabolic products are the actual target products (e.g. vitamins, amino acids, organic acids such as citric acid and acetic acid, enzymes, antibiotics, bioethanol, biomonomers and polymers such as polyhydroxyalkanoates (PHA), polyhydroxybutyric acid (PHB) or polylactic acid (PLA).

- Bioplastics: Biodegradable starch-based materials can be produced from potatoes, corn and wheat. In addition, a variety of other renewable raw materials are suitable for the production of bioplastics.

Starch is also used as a raw material for building materials (flowable concrete, mortar), paste and packaging materials (foamed starch) as well as washing powder (sugar surfactants, laundry starch), animal feed, films and cosmetics.

Figure 8: Renewable raw materials for the production of bioplastics, adapted from

5

Sugar: sweetener and platform chemical

Sugar based on renewable raw materials occurs in nature in many different ways - as sugar in sugar beet, cellulose in wood or starch in potatoes.

- Starch-based sugars are primarily glucose syrup, dextrose and isoglucose.

- Hemicelluloses and celluloses are suitable for the production of glucose, which can be used as a substitute for conventional glucose as a fermentation raw material.

- Sugar cane and sugar beet form the raw material basis for sucrose (household sugar).

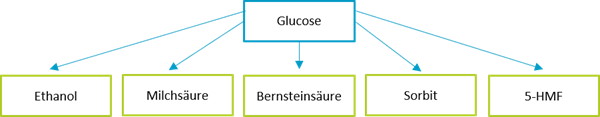

Sugar also forms the starting point for the production of other products and is very suitable for the synthesis of platform chemicals:

- Bioethanol (platform chemical, food, energy carrier)

- Lactic acid (platform chemical, production of bioplastics, among other things)

- 5-hydroxymethylfurfural (platform chemical)

- Succinic acid (platform chemical, food additive)

- Sucralose, isomaltulose, invert sugar (sweeteners)

- Sucrose esters, sucrose ethers, glucamides, alkyl polyglucosides (surfactants)

- Sorbitol, mannitol, xylitol (sugar alcohols)

- Carboxylic acids such as gluconic acid and glucuronic acid (acidity regulator, stabiliser, metal pickling agent)

- Itaconic acid (e.g. for biodegradable polymers in the packaging industry, lacquers, paints)

- Glutamic acid (glutamate)

- Furfural (solvent, drug)

Starting from glucose, the following synthesis building blocks can be produced, for example.

Figure 6: Basic chemicals based on glucose, adapted from

3

Oils and fats: surfactants, bioplastics and paints

From a chemical point of view, vegetable oils and fats are mixtures of glycerol fatty acid esters with predominantly long-chain carboxylic acids, the so-called fatty acids. These compounds are also called triglycerides. Triglycerides with the highest possible proportions of certain fatty acids are of interest for industrial use (e.g. rapeseed, sunflower, oil flax, camelina, poppy seed).

Fatty acids and fatty acid derivatives based on renewable raw materials are mainly needed for

surfactants for the production of detergents and cleaning agents. According to the European industry association CESIO, surfactants with at least one building block from renewable raw materials have already achieved a relative share of more than 50 per cent of the total surfactant market in Europe. This share is expected to increase further.

In addition, they are processed in the pharmaceutical, cosmetics and textile industries and are important raw materials for biolubricants and oils, polymers and polymer additives, coatings and paints as well as bioplastics (polyhydroxy fatty acids: PHB, PHV).

Terpenes: fragrance, aroma and solvent

Terpenes are the main component of essential plant oils and thus belong to the secondary ingredients. Well-known examples are menthol, which occurs in peppermint oil, or the couminal in cumin and eucalyptus. Large quantities of terpenes are present in natural rubber and in turpentine oils, which can be obtained from conifers (pines). Among other things, terpenes can be used as

solvents, antimicrobial agents, therapeutics, flavours or odorants.

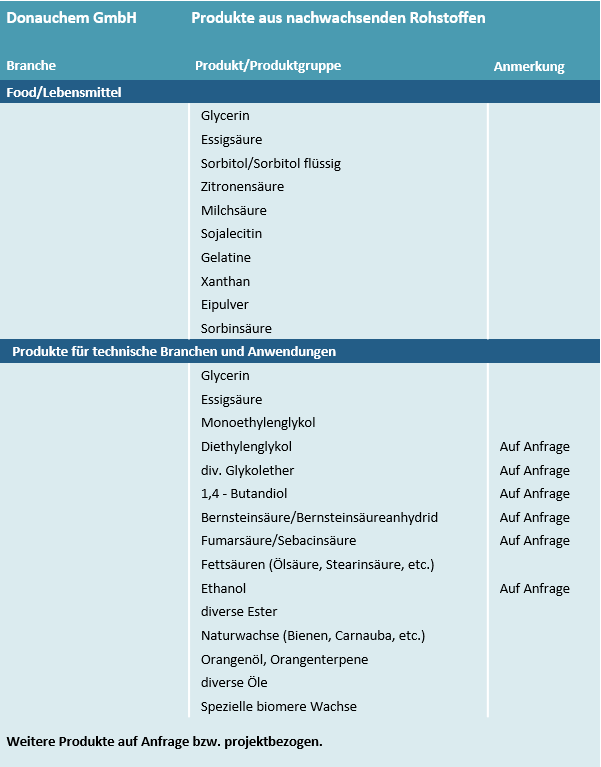

Donauchem product portfolio for renewable raw materials

As a sustainable company, Donauchem is constantly adding new products based on renewable raw materials to its product portfolio:

Conclusion: Renewable raw materials for green chemistry

Biomass contains not only carbohydrates such as cellulose, hemicellulose, starch and sugar, but also other basic products such as lignin, terpenes and fats. These raw materials can be used to produce renewable platform chemicals by converting them into raw materials suitable for the chemical industry. This is then followed by the processes of the chemical industry again for the production of further sustainable products.

Do you have any questions about our products made from renewable raw materials? We look forward to receiving

your inquiry!

www.donauchem.at

Sources/related links:

www.donauchem.at

Sources/related links:

[1]

SDG Unterziel 12.2. Inländischer Materialverbrauch pro Kopf in Österreich. Statistik.at. page visited on 26. September 2022, https://statistik.at/services/tools/services/indikatorensysteme/sdgs/ziel-12-verantwortungsvolle-konsum-und-produktionsmuster/unterziel-122

[2]

Behr, A., & Seidensticker, T. (2018). Einführung in die Chemie nachwachsender Rohstoffe: Vorkommen, Konversion, Verwendung. Springer Berlin Heidelberg.

[3]

Nachwachsende Rohstoffe. Vci.de. page visited on 27. September 2022, https://www.vci.de/fonds/downloads-fonds/unterrichtsmaterialien/nachwachsende-rohstoffe/textheft-inkl-arbeitsblaetter-und-experimente.pdf

[4] DDI Wolfgang Aichhorn, M. B. A..

Innovative Nutzung von Nebenströmen aus dem Sulfitverfahren. Gigkarasek.com. page visited on 28. September 2022, https://www.gigkarasek.com/de-at/blog/nutzung-nebenstroeme-sulfitverfahren

[5]

Biobasierte Materialien – Werkstoffe und Textilien. Biooekonomie.de. page visited on 27. September 2022, https://biooekonomie.de/themen/dossiers/biobasierte-materialien-werkstoffe-und-textilien